Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

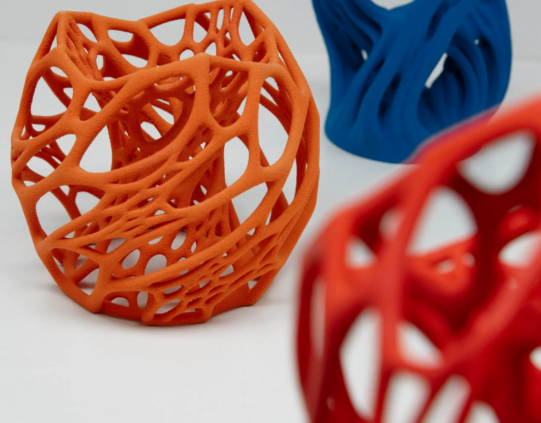

With its excellent performance and wide applicability, polysilazane resin is driving 3D printing additive manufacturing technology towards high performance, personalization, and green development. The following is a comprehensive analysis:

1. Popular Science of Polysilazane Resin and 3D Printing Additives

The following are its core features and application advantages:

High Hardness and Wear Resistance: After curing, the hardness can reach over 8H, effectively resisting friction and wear, making it suitable for parts requiring high wear resistance.

High Temperature Resistance: It can withstand temperatures exceeding 1800°C, has low thermal weight loss, and a ceramic yield of over 80%, making it suitable for applications in high-temperature environments.

Corrosion Resistance: It has excellent resistance to acids, alkalis, and solvents, protecting printed parts from chemical attack.

Strong Adhesion: It bonds well to a variety of substrates, including metal, glass, and ceramics, ensuring the stability of printed parts.

Simplified Process: It eliminates the need for traditional degreasing and high-temperature sintering processes, completing the entire process from gel extrusion to curing in a single step, improving production efficiency.

3D printing additive manufacturing is a technology that builds three-dimensional objects by adding material layer by layer.

2.Application Principle

The principle of Stereo lithography Apparatus: Specific functional groups (such as acrylate groups) in polysilazane resin undergo a photochemical reaction when exposed to light of a specific wavelength, initiating crosslinking and curing of the resin’s molecular chains. By irradiating the photosensitive resin layer by layer, it cures layer by layer, creating the desired three-dimensional object.

Pyrolytic Ceramics: Polysilazane resin undergoes pyrolysis at high temperatures, causing its organic components to decompose and release gases, while simultaneously forming ceramic phases (such as SiC and Si₃N₄). This ceramicization process imparts excellent high-temperature and corrosion resistance to printed objects, making it suitable for applications requiring high material performance.

3.Application advantages

Excellent High-Temperature Resistance

Polysilazane resin achieves a hardness of over 8H after curing, can withstand temperatures exceeding 1800°C, has low thermal weight loss, and achieves a ceramic yield exceeding 80%. Compared to traditional 3D printing materials, its high-temperature stability makes it suitable for applications requiring extremely high-temperature resistance, such as aerospace and automotive. It can directly print high-temperature resistant parts without the need for subsequent high-temperature treatment.

Simplified Process

Traditional metal or ceramic 3D printing requires complex steps such as degreasing and sintering. However, polysilazane resin can be converted into an inorganic ceramic at just 900°C, eliminating the need for degreasing and significantly reducing the sintering temperature, significantly shortening production cycles and reducing costs.

Excellent Mechanical Properties

Polysilazane resin exhibits high strength and toughness after curing, and its mechanical properties can be manipulated through molecular design. For example, by introducing dynamic chemical bonds (such as urea bonds), toughening can be achieved during post-molding processing, improving the product’s impact and fracture resistance and meeting the performance requirements of complex structural parts.

Material Compatibility and Versatility

Polysilazane resin can be compounded with other materials (such as ceramic powder and metal powder) to achieve multi-material integrated printing. Furthermore, its hydrophobic, wear-resistant, and corrosion-resistant properties offer broad application potential in areas such as anti-corrosion coatings and electronic packaging, enabling the direct printing of functionally specific structural components.

Environmental Protection and Sustainability

Compared to traditional materials, the synthesis and use of polysilazane resin has a lower environmental impact. Its low viscosity allows for easier flow during printing, reducing material waste and aligning with the trend toward green manufacturing.

In summary, polysilazane resin materials, through their unique properties and process advantages, provide a new breakthrough direction for 3D printing additive manufacturing in the production of high-performance, complex structural parts, especially in high-end manufacturing fields such as aerospace, automobiles, and electronics.