Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

About Organic Polysilazanes

Polysilazanes are polymers with alternating silicon and nitrogen atoms forming their basic backbone, represented by the molecular formula [R1R2Si-NR3]n. R1-R3 can be hydrogen atoms or organic substituents.

If all substituents are hydrogen atoms, the polymer is called perhydropolysilazane (PHPS) or inorganic polysilazane [H2Si-NH]n.

If hydrocarbon substituents are attached to silicon atoms, the polymer is called organic polysilazane (OPSZ).

Organic polysilazanes materials can rival traditional film-forming materials used in the coatings industry in many applications and offer significant performance advantages in certain areas. These coating systems exhibit superior performance, extended service life, and excellent adhesion to substrates.

Product Details

| Name | Organic polysilazane |

| Other Names | OPSZ |

| Chemical Formula | [R1R2Si-NR3]n |

| CAS Number | 475645-84-2 |

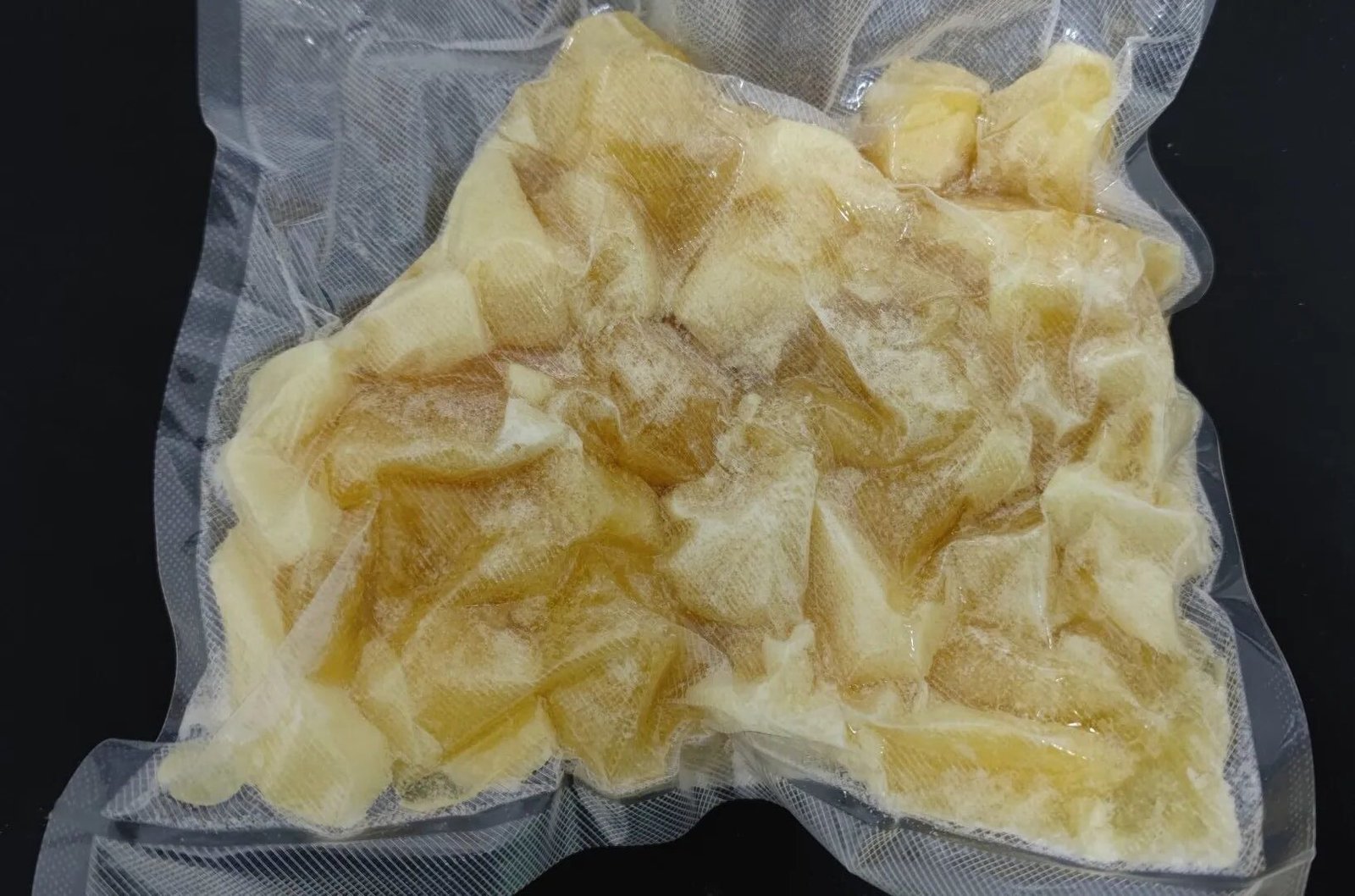

| Appearance | Colorless, transparent to pale yellow liquid |

| Applications | Industrial coatings, adhesives, ceramic precursors, composites, and coatings |

| Hazard Statements | Highly flammable liquid and vapor; harmful if swallowed; damages eyes |

Product Application

Organic polysilazanes can form cold-blended mixtures with most resins that do not react chemically with it, such as thermoplastic acrylic, silicone, organic polysilazane and inorganic polysilazane mixtures.

When organic polysilazane is heated to a minimum of 450°C, the polymer is ultimately converted into an inorganic ceramic (SiOx). This inorganic ceramic exhibits extremely high hardness (9H) and exceptional heat resistance (up to 1800°C).

Polysilazanes are widely used in clearcoat formulations, offering excellent resistance to weathering, UV light, corrosion, stains, graffiti, scratches, and heat. Dry film thicknesses for organopolysilazane clearcoats typically range from 2 to 10 µm, while those for inorganic polysilazane clearcoats typically range from 10 nm to 1 to 2 µm.

Compared to aminoalkyd and two-component polyurethane systems, organopolysilazanes offer superior gloss retention and weather resistance. Compared to silicone-modified polyester systems, organopolysilazanes exhibit superior heat resistance. Aluminum coated with organopolysilazane coatings showed no corrosion after 2400 hours of salt spray testing (ISO 7253). Steel coated with organopolysilazane coatings showed no corrosion after 2400 hours of condensation water climatization (ISO 6270). The water contact angle of organopolysilazane resins is approximately 95° and remains stable over time. Using suitable modifiers, the water contact angle of modified organopolysilazane coatings can be increased to over 120°.

Applications of polysilazane

Industrial coatings: High-temperature, corrosion-resistant, fire-resistant, anti-fouling, waterproof, wear-resistant, heat-resistant/insulating, paint-resistant, easy-to-clean, and easy-to-release coatings.

Binders: Ceramics, metals, glass, and organic materials.

Ceramic precursors: Ceramic binders, ceramic-based composites, metal-based composites, and ceramic fibers.

Composites and coatings: Polyurethane, silicone, epoxy resin, and acrylic resin.

Product Model

Note:

Organopolysilazane must be used in a ventilated, dry environment and with necessary protective measures, such as gloves and a mask.

Uncured organopolysilazane must not be placed near sources of fire, humid air, or water.

Opened containers must be resealed promptly after use. If used in a humid environment, flush the container with nitrogen after use.