Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Adaptive broad-spectrum anti-adhesion “polymer ceramic” coating

Surface adhesion is a common phenomenon in daily life and industrial production. However, some undesirable surface adhesions (such as biofouling, oil, ice, and scaling) can cause serious economic losses and safety hazards. For example, biofouling on ship surfaces can increase their sailing resistance and significantly increase fuel consumption; bioadhesion on medical equipment can increase the risk of infection. The adhesion of liquids such as oil and graffiti can reduce the clarity of transparent windows or displays, affecting their normal use. The adhesion of solid materials, such as scaling in transportation pipelines or ice on outdoor facilities, can seriously affect heat exchange efficiency, causing safety hazards and huge economic losses.

Anti-adhesion coatings have become a hot topic in academia and industry due to their simplicity, efficiency, and cost-effectiveness. Currently, low-surface-energy materials such as organosilicon and organofluorine have been used to impart anti-adhesion properties to coatings, both for liquids and solids. Hydrophilic polymers with strong hydration capacity, such as polyethylene glycol or zwitterionic polymers, can be used to create anti-biofouling coatings.

However, these coatings typically lack simultaneous resistance to liquids, solids, or biofouling. Furthermore, the inherently poor mechanical properties and durability of organic polymers limit their industrial applications. Designing and fabricating functional coatings that combine high mechanical properties with broad-spectrum anti-adhesion properties, such as high strength, high adhesion, high transparency, and resistance to biofouling, oil, and scaling, is extremely challenging.

The Marine Engineering Materials Team at South China University of Technology has long been dedicated to the research of polymer materials for special and extreme service environments. In recent years, they have conducted extensive research on functional materials with both “ceramic-like” and “polymer-like” properties (i.e., polymer ceramics). They have developed multifunctional silicon-based flexible hard antifouling coatings, zwitterionic zirconium-silicon cluster-based flexible hard antifouling coatings, recyclable flexible hard anti-adhesion coatings, and self-healing flexible hard water-based anti-adhesion coatings.

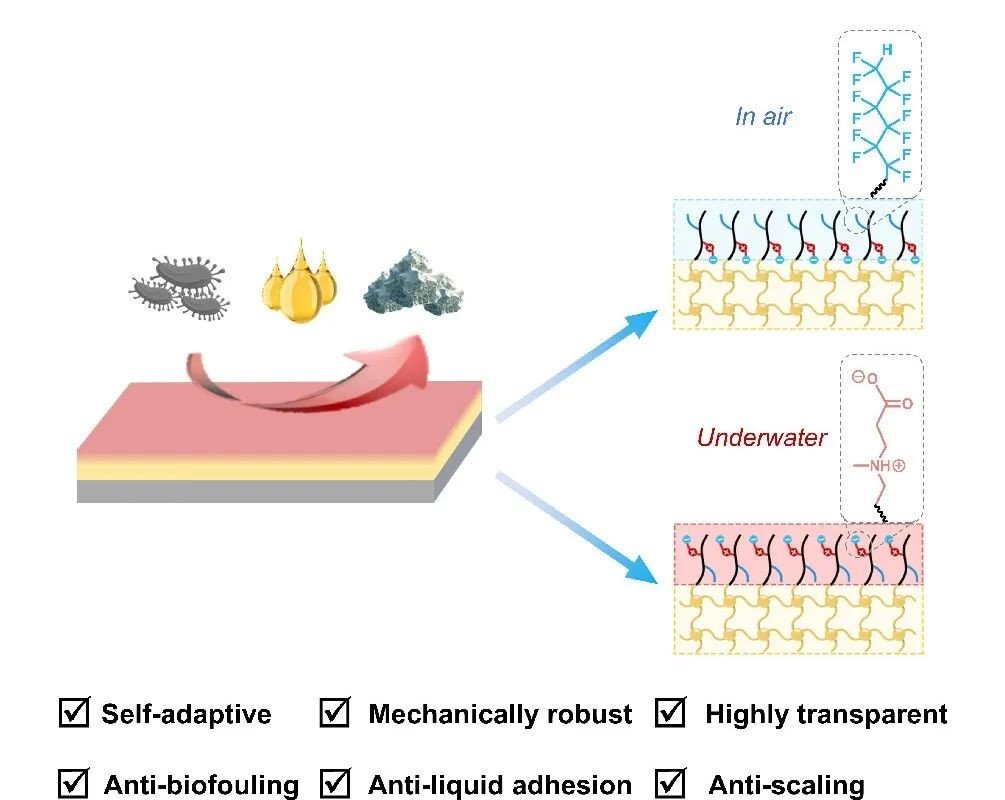

Recently, building on their previous work, the team designed and fabricated an adaptive zwitterionic polysilazane coating based on a surface self-accumulation strategy. This coating achieves a broad-spectrum anti-fouling, anti-oil, and anti-scale resistance. Furthermore, the coating exhibits high strength, wear resistance, adhesion, and transparency.

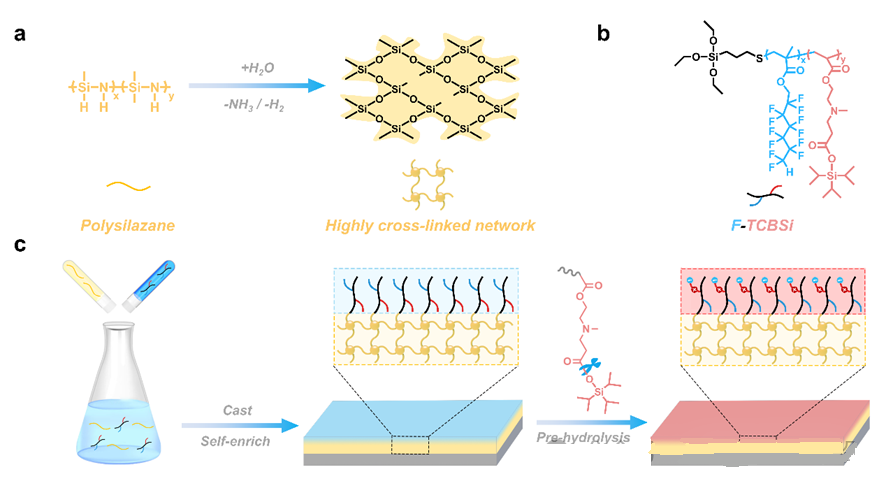

Polysilazanes are a class of polymers whose molecular backbones consist of alternating silicon and nitrogen atoms. They can be transformed into hard coatings characterized by a high-crosslink density Si-O-Si network. Compared to coatings prepared by conventional sol-gel reactions, these coatings offer unique advantages, such as enhanced adhesion and ease of chemical modification.

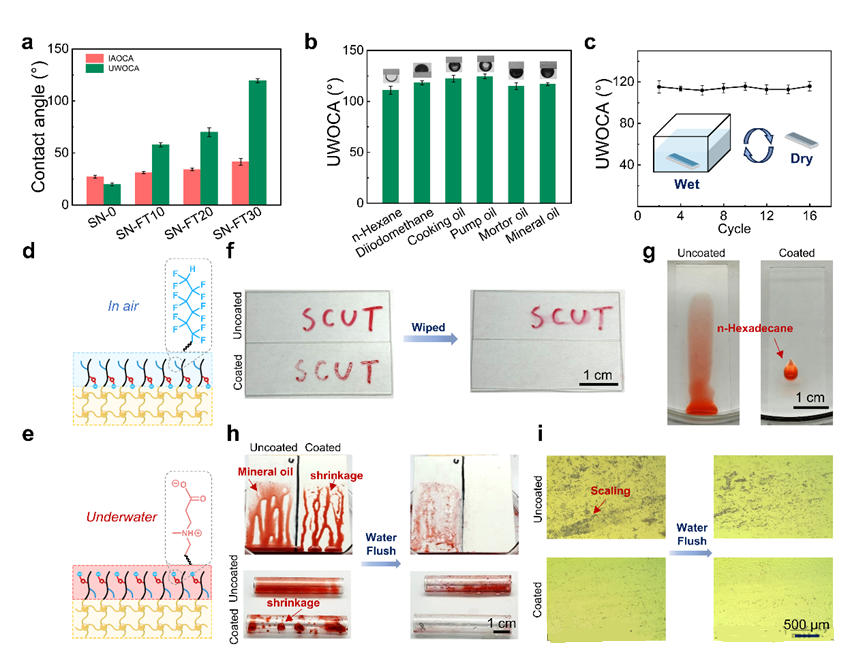

This coating, based on polysilazanes, innovatively incorporates a functional telomer (FT) consisting of low-surface-energy fluorinated segments and hydrolysis-induced zwitterionic segments. During the coating formation process, the fluorinated segments drive the self-accumulation of the functional telomer on the surface, where they form a zwitterionic polymer layer after pre-hydrolysis. This unique design prevents the coating from swelling in water. In particular, the low surface energy of the fluorinated segments and the strong affinity of the zwitterionic segments for water give the coating unique adaptive properties. In air, the fluorinated segments migrate to the surface, imparting anti-oil and graffiti properties. Underwater, the zwitterionic segments migrate to the surface, imparting anti-biofouling, anti-submerged oil adhesion, and anti-scaling properties. The highly cross-linked network toughened by FT gives the coating a flexible and hard property, combining high hardness (up to 7H) with good flexibility (1 mm bending diameter), while the chemical bonding between the coating and the substrate gives the coating strong adhesion (2.06-7.67 MPa).

In summary, this work cleverly combines adaptive and surface self-accumulation strategies to successfully prepare adaptive zwitterionic polysilazane coatings that exhibit flexibility, rigidity, high wear resistance, strong adhesion, high transparency, and anti-biofouling, anti-liquid adhesion, and anti-scaling properties. This research provides new insights into the design and preparation of functional coatings that combine high mechanical properties with broad-spectrum anti-adhesion properties. These coatings have potential applications in the marine industry, optical equipment, pipeline transportation, and other fields.