Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

ZhengZhou Quartz Master New Materials Co., Ltd. is dedicated to the development and application of polymer-derived ceramic precursor resins. High-performance polymer-derived ceramic precursor resins are one of the key raw materials blocked by foreign countries from China.

In recent years, they have shown tremendous application potential in numerous high-end fields, including petrochemicals, aerospace, marine engineering, photovoltaic cells, porous ceramics, high-temperature resistant coatings, ceramic fibers, and ceramic-based composites.

The company is currently collaborating with Sinopec, PetroChina, and other companies to develop products for applications in the petrochemical industry, including high-temperature resistance, erosion resistance, corrosion resistance, and anti-coking.

Polymer-derived ceramic precursors

Polymer-derived ceramic precursors are a class of organic polymer materials with unique properties and broad application prospects. Their backbones are composed of repeating -5i-N- units, with molecular weights (Mw) > 200,000 g/mol. Their exceptional solubility and meltability offer significant advantages in various processing techniques. Notably, they spontaneously crosslink at high temperatures, transforming into stable inorganic silicon-nitrogen-carbon or silicon-nitrogen ceramics. This characteristic imparts remarkable thermal stability and exceptional chemical inertness.

Key Applications:

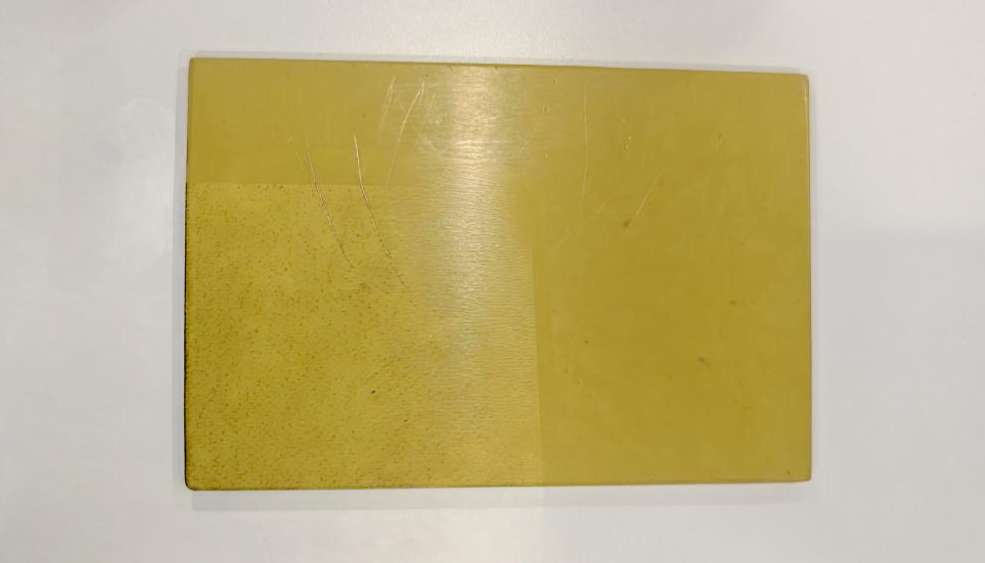

High temperature resistant polymer derived ceramic precursor plastics

This product utilizes our company’s independently developed polymer-derived ceramic precursor resin as a matrix, incorporating high-temperature-resistant active fillers, reinforcing fibers, additives, and auxiliaries. This high-temperature-resistant polymer-derived ceramic precursor plastic exhibits excellent thermochemical stability and thermodynamic properties. The synergistic use of high-temperature active fillers and reinforcing fibers ensures mechanical strength at varying temperatures.

This new plastic is dense, waterproof, and resistant to high temperatures, acid, alkali, and salt spray corrosion, aging, and wear. It addresses the issues of traditional plastics with low mechanical strength and susceptibility to corrosion and oxidation in high-temperature environments.

Key Features:

Designed Applications:

Can be used in aerospace high-temperature composite structural materials, electronic packaging materials, semiconductor packaging materials, high-temperature corrosion-resistant structural components, and high-temperature combustion chamber interiors to protect against oxidative corrosion. New energy vehicle battery packs with high-temperature corrosion resistance are also used. They can also be used in the nuclear power, hydrogen fuel, energy, petrochemical, marine engineering, automotive, metallurgical, and other manufacturing industries. They can also be used for high-temperature special switchgear and socket strips, and for heavy-duty corrosion and oxidation protection of offshore platform structures.