Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

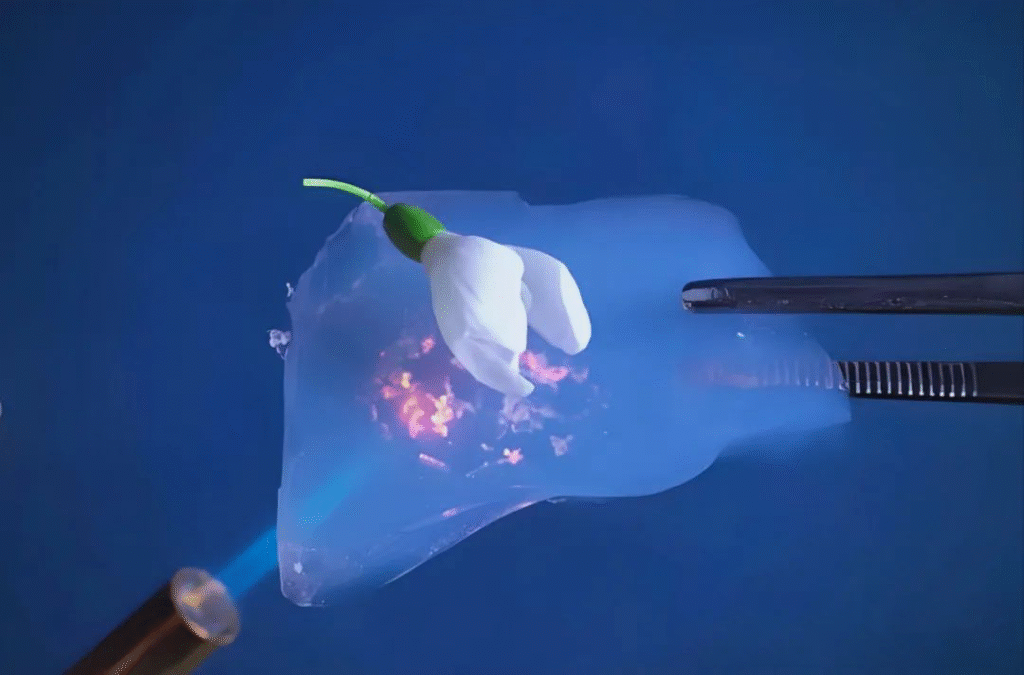

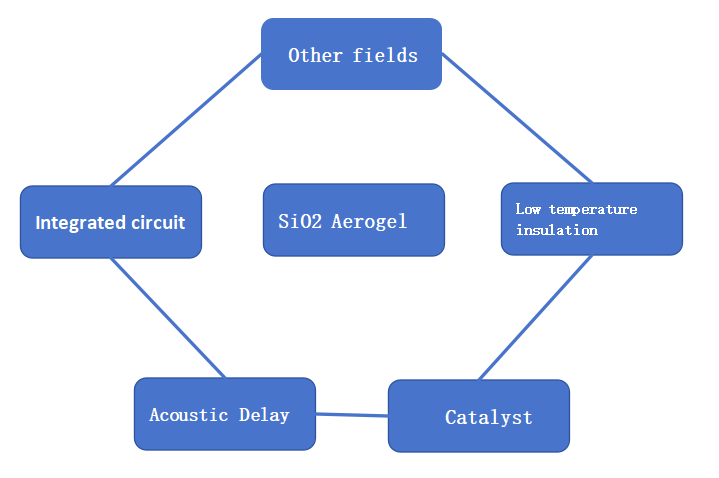

What is aerogel? The world’s first SiO2 aerogel was prepared from a bet between foreign scientists and friends about “exchanging liquid for gas in jelly”. The publication of “Copolymerization and Diffusion Aerogel and Jelly” in Nature in 1931 marked the official launch of aerogel. To understand what aerogel is, we must first start with gel. The so-called gel refers to a polymer solution or sol of a certain concentration. Under appropriate conditions, as the viscosity gradually increases, it finally loses fluidity and becomes a plate-like or elastic semi-solid with a uniform appearance and a certain shape. When the gel is filled with water or other liquids, it is called a hydrogel. When the gel is filled with gas, it is called “aerogel”. Aerogel is a highly dispersed solid material in which colloidal particles are agglomerated to form a nanoporous network structure and the pores are filled with a gaseous dispersion medium. Aerogel has extremely high porosity, extremely low density, high specific surface area, and ultra-high pore volume rate. As an excellent thermal insulation material, aerogel insulation felt can withstand high temperatures of at least 400°C. The magical aerogel can also withstand baking at temperatures of up to 1500°C. Secondly, it can be used as an adsorbent to absorb oil and other toxic organic matter from water. Thirdly, the low sound velocity and high porosity of aerogel make it an ideal acoustic impedance coupling material and underwater acoustic anti-sound material. In 2021, it was listed as the first of the ten new materials that can change the world today.

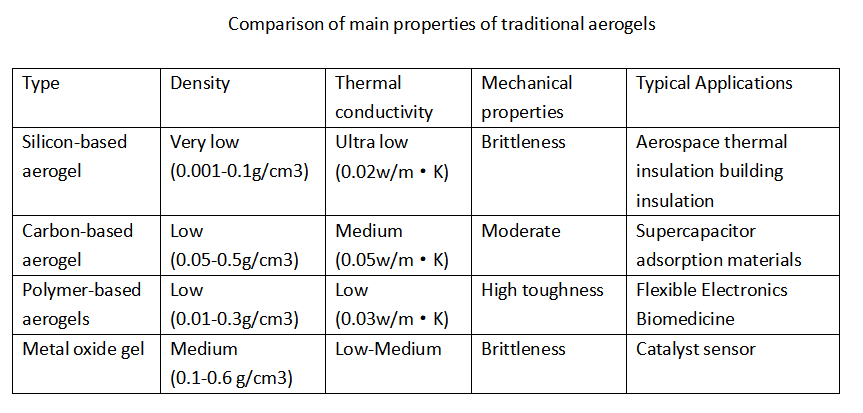

Existing aerogel types and their properties: Aerogel, as a lightweight material with a nanoporous structure, is known for its extremely low density, high specific surface area and excellent thermal insulation performance. According to different components and structures, traditional aerogels can be divided into many types, each with unique characteristics and application areas.

The following are the main types and their characteristics: Silicon-based aerogel (SiO₂ aerogel): As the world’s first aerogel, after nearly a century of development and changes, silicon-based aerogel, known for its ultra-low thermal conductivity (0.013–0.025 W/m·K), is still one of the best solid thermal insulation materials at present, with a high porosity of up to 90–99.8% and a density as low as 0.001 g/cm³ (lighter than air). The most common type is based on silicon dioxide (SiO₂) as the skeleton. It is transparent or translucent, with good light transmittance (visible light band); the disadvantage is that it is brittle and has low mechanical strength, and needs to be reinforced with fibers (such as glass fibers) or polymer modified to improve toughness. At present, it is mainly used in: spacecraft insulation (such as NASA’s Mars rover); building energy-saving glass, pipeline insulation; high-temperature insulation of industrial equipment, etc.

Carbon-based aerogel (carbon aerogel): It is characterized by excellent conductivity, adjustable resistance, and is suitable for electrochemical applications. It has a high specific surface area (500–2500 m²/g), high adsorption energy; high temperature resistance (can withstand more than 2000°C under inert atmosphere); high hydrophobicity, and can be modified to achieve hydrophilicity. It is black and opaque, and its mechanical properties are better than those of silicon-based aerogels. It is mainly used in: supercapacitors, lithium-ion battery electrode materials; oil or organic solvent adsorption (such as offshore oil spill treatment) and electromagnetic shielding materials.

Metal oxide aerogel (such as Al₂O₃, TiO₂, ZrO₂, etc.): It has high chemical stability, corrosion resistance and high-temperature oxidation resistance. And high catalytic activity, multiple surface active sites (such as TiO₂ photocatalytic degradation of pollutants). Excellent dielectric properties (such as Al₂O₃ for electronic devices). Usually white or light-colored powder with low mechanical strength. Mainly used in: catalyst carriers (petrochemical industry, environmental purification), sensors and optical coatings, etc.

Polymer-based aerogels (such as cellulose, polyimide, chitosan, etc.): They overcome the brittleness of traditional aerogels and are flexible and can be bent or even folded; they are biocompatible (such as cellulose, chitosan PLA), and degradable; they have low density but high strength, and some types are comparable to engineering plastics. They can be prepared from natural polymers (such as cellulose) with low environmental protection costs. They are mainly used in: flexible electronic devices, wearable devices; biomedicine (drug sustained release, tissue engineering scaffolds) and environmentally friendly packaging materials.

Hybrid/composite aerogels: They are multifunctional, and can achieve performance optimization and enhance mechanical properties by combining different materials (such as SiO₂+polymers, carbon+metal oxides); they can precisely control the pores and customize the pore structure through templates or 3D printing. However, the product structure is complex, and its compatibility and integrity are poor. They are mainly used in high-performance sensors (such as graphene-SiO₂ composite aerogels); multifunctional thermal insulation materials (such as flame-retardant polyimide aerogels).

Other new aerogels: such as graphene aerogel, which has both high strength and conductivity. It is ultra-light (density can be as low as 0.16 mg/cm³), highly conductive, and can be used in flexible electronics and energy storage: MXene aerogel, with high conductivity and capacitance, is suitable for electromagnetic shielding and energy storage. Biomass aerogel, derived from wood, seaweed, etc., is sustainable and low-cost, and can be used for adsorption or insulation.

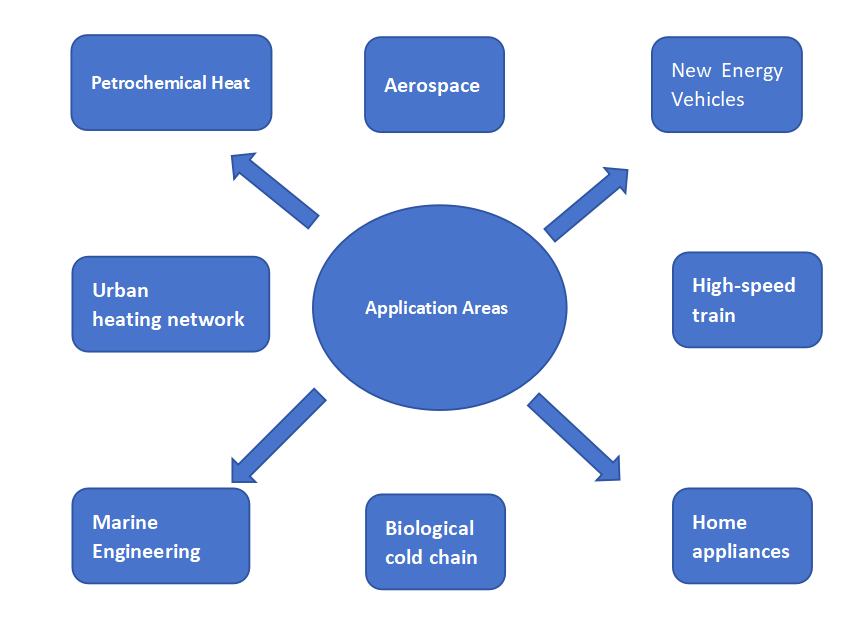

In summary, the current aerogel materials have the width and depth of single aerogel material performance, and the material performance needs to be upgraded and multifunctionalized. Develop atmospheric pressure drying technology to reduce energy consumption; improve sol-gel process and supercritical drying technology to achieve low-cost large-scale production; improve the incompatibility caused by the composite of single aerogel multiple materials (such as the existing traditional silicon-based aerogels need to be composited with glass fiber and other materials). Develop and find multifunctional integrated aerogel basic materials that have both thermal insulation, flame retardancy and energy absorption, excellent dielectric properties, high hydrophobicity and high mechanical strength, as well as high temperature resistance, aging resistance and long-lasting stable coatings. Expand the application of aerogels from “high-end special materials” to civilian fields (such as home appliance insulation, outdoor clothing and other protective products).

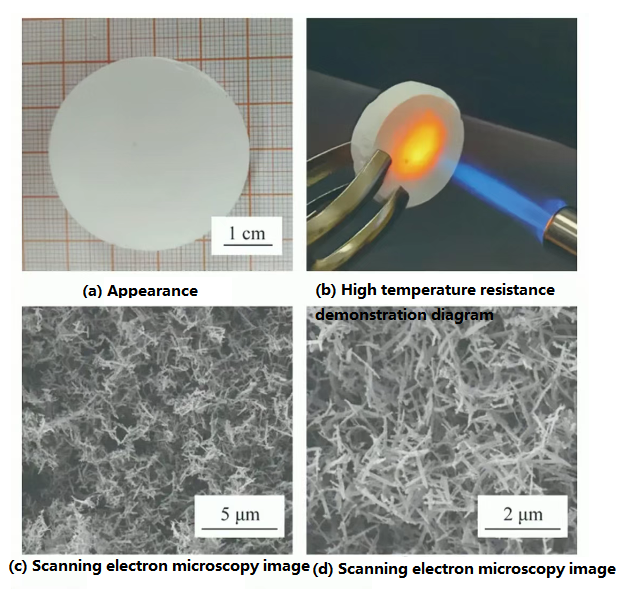

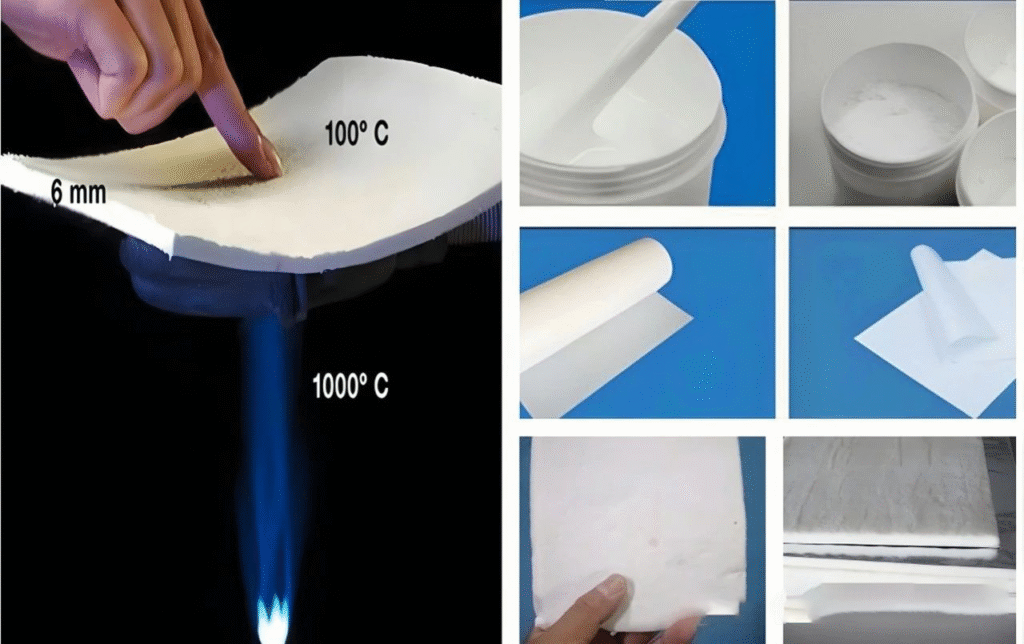

Polysilazane, an organic-inorganic hybrid polymer with Si-N as a repeating main chain, contains three elements of silicon, nitrogen and carbon in its structure, and has the characteristics of low density, high porosity, light weight and high modulus. Silicon nitrogen resin not only has the excellent electrical, thermal conductivity and mechanical properties of silicon, but also has the good high insulation, oxidation resistance and corrosion resistance of silicon nitride. Organic silicon nitrogen resin can be converted into inorganic compounds such as SiCNO, SiCN or silicon dioxide ceramics under high temperature conditions. After curing, the hardness can reach more than 8H, and the temperature resistance can reach more than 1800℃. It has good thermal stability, mechanical properties, dielectric properties and insulation, high temperature resistance, corrosion resistance, high hardness, UV transparency, flame retardant and heat insulation, hydrophobicity and low surface energy performance. Today, this new type of silazane silicon-based aerogel has the performance characteristics of low density, low thermal conductivity, flame retardant and heat insulation and adsorption energy, high hydrophobicity, aging resistance and high mechanical strength. The Quanzhou team of Zhongsi New Materials, which broke through the “bottleneck” project of polysilazane, created miracles again. Silazane’s flame retardant, heat insulating and thermal insulation properties and its porous structure have adsorption capacity, enabling the “return of the king” of silicon-based aerogel, which has been on the market for a century.

Developed by the Quartz master new material ZhengZhou team, Silazane Aerogel is a high-porosity nanoporous material synthesized from Silazane precursors by the sol-gel method. Its working principle is mainly based on its unique chemical composition and microstructure. Its main function is to chemically modify the active functional groups such as hydroxyl and carboxyl groups on the surface of the aerogel to form siloxane bonds and silicon-nitrogen bonds, thereby improving the performance of the aerogel. The principle is that the nitrogen atoms in the silazane molecules react with the active functional groups on the surface of the aerogel to form silicon-nitrogen bonds, and form a cross-linked structure between the siloxane bonds and nitrogen atoms, thereby improving the stability and mechanical properties of the aerogel.

Chemical structure and thermal stability of silazane aerogel: Silazane aerogel has Si-N bonds as its skeleton (may contain a small amount of Si-O bonds), and has higher thermal stability and chemical inertness than traditional silica aerogel (Si-O bonds); it can withstand high temperatures above 1000°C in an inert atmosphere or ammonia, and the Si-N bond energy (about 435 kJ/mol) is higher than that of the Si-O bond (about 452 kJ/mol), but it may gradually convert into Si-O bonds in an oxidizing environment; a dense SiO₂ layer can be formed on the surface of the cured film to prevent further oxidation (similar to the protection mechanism of SiC materials), and it has the characteristics of aging resistance and oxidation resistance.

The porous structure of silazane aerogel: Silazane has ultra-high porosity (>90%), nanoscale pores (2-50 nm) and three-dimensional network structure, giving it extremely low density (0.01-0.2 g/cm³) and ultra-high specific surface area (500-1200 m²/g); it has ultra-low thermal conductivity of only 0.015-0.03 W/m·K, and the pore size is smaller than the free path of air molecules (~70 nm), which inhibits gas convection and heat conduction, making it a highly efficient thermal insulation material; it has excellent low dielectric constant (1.1-2.5), and is also suitable for high-frequency electronic device packaging.

Surface chemical modification and functionalization of silazane aerogel: The high hydrophobic characteristics of silazane can be further hydrophobically modified by introducing organic groups such as -CH₃ (such as trimethylsilazane) with a contact angle of >150°, which can be used for waterproof coatings or oil-water separation; as a catalytic carrier, silazane’s high specific surface area and active Si-NH/Si-H sites can load metal nanoparticles (such as Pt, Ni) for catalytic reactions (such as hydrogenation and cracking). In addition, by adding fibers or nanofillers (such as carbon nanotubes), the compressive strength can be increased from 0.1 MPa to 10 MPa.

Wide application fields and mechanism of action of silazane aerogel: Silazane aerogel is widely used in aerospace insulation and used in aircraft thermal protection systems (TPS). It reflects radiant heat and blocks conductive heat through porous structures. As well as outdoor thermal insulation materials such as home appliance insulation and chemical oil and gas pipelines; silazane aerogel uses pores to limit the polysulfide shuttle effect. As a separator for lithium-sulfur batteries, and aerogel insulation pads for supercapacitors and lithium-ion batteries; Silazane aerogel has the adsorption and purification function, and its nanopores selectively adsorb VOCs or heavy metal ions (such as Hg²⁺), relying on the chemical bonding of surface functional groups. It is also suitable for oil or organic solvent adsorption (such as offshore oil spill treatment) and electromagnetic shielding materials. In the biomedical field, the controllably degradable Si-N skeleton of silazane aerogel can be used as a drug sustained-release carrier (pH-responsive release).

In the future, silazane aerogel will have unlimited potential in extreme environment applications (such as nuclear protection and deep space exploration) due to its performance advantage of “strong chemical bonds + nano-porosity” synergistic effect. Silazane’s flame retardancy, heat insulation, aging resistance, low thermal conductivity, high mechanical strength and other properties and the adsorption capacity of its porous structure will enable the return of the century-old silicon-based aerogel king and continue its legend.