Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Graffiti damage is a major public nuisance to modern civilization, staining surfaces with unpleasant images or text, and even damaging structures. The most effective way to combat graffiti is with anti-graffiti paint, particularly permanent anti-graffiti paint. Its hard, abrasion-resistant surface lasts up to 10 years, making it difficult to stain or easy to remove.

Faced with such a great hazard, how should we solve it and take preventive measures?

First of all, we should know the principle of anti-graffiti:When we paint on the paint film with water-based or oil-based pens, the ink will seep into the gaps and the graffiti will become indelible.

So how can we prevent ink from entering the gaps? We only need to form a low surface tension molecular layer on the surface of the paint film to prevent ink from penetrating.

According to our research, the resins currently used in anti-graffiti coatings include polyurethane, fluororesin, fluorosilicone resin, water-based polyurethane, and water-based cross-linked fluororesin. Silicone/fluorine is commonly used for anti-graffiti coatings, with silicone dominating the market (due to the relatively high price of fluorine).

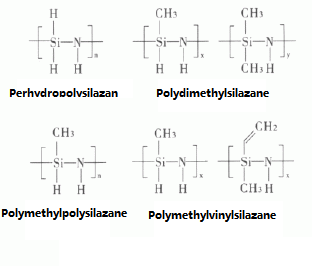

Today, ZhengZhou Quartz Master New Materials Company would like to recommend a newly developed “polysilazane” material.Polysilazanes are polymers of silicon, nitrogen, and hydrogen. Organopolysilazanes are made from carbon, industrial ammonia, and the corresponding chlorosilanes.

Organopolysilazanes can be formulated into various coatings with versatile properties, including extremely high hardness and scratch resistance, high chemical and corrosion resistance, temperature stability, easy cleaning, and barrier properties. They are excellent protective coatings for glass, polycarbonate, organic glass, polyester, aluminum, and steel.

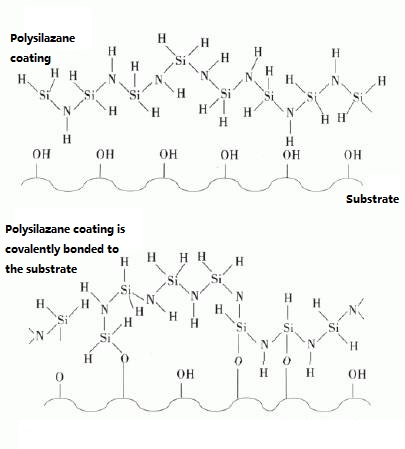

A key application of polysilazane is as an anti-graffiti coating or protective layer. It can be applied to buildings and public transportation vehicles to prevent graffiti, typically caused by spray paint or ink, thereby saving significant costs. EK-S02 anti-graffiti coating made from polysilazane requires only 5μm to effectively combat graffiti. It dries to the touch in just one hour at room temperature and fully cures after several days. Its high crosslink density and low surface energy (105 mN/m) make it particularly resistant to the penetration of inks and pigments.

Weathered coatings can also be topcoated with polysilazane-based coatings, currently used on European rail systems. Polysilazane coatings not only protect the surface from graffiti, but also resist grime in underground mining areas and on walls stained by vandalism. The coating’s protection allows for high-pressure cleaning to remove dirt.

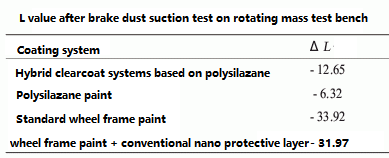

Polysilazane coatings are also suitable for dust-resistant aluminum wheel rims. Braking causes road dust and impurities to accumulate on the wheel rims within a short period of time. Braking can reach temperatures of 500°C or higher, and conventional surface coatings discolor at these temperatures, making them difficult to remove.

Tests have shown that polysilazane coatings offer significantly better dust and discoloration protection than other existing systems.

In the face of some complex situations, such as high temperatures above 1000 degrees, or in acidic and alkaline conditions, the polysilazane coating will be quickly destroyed. So how should we deal with such situations?

We can modify polysilazane. The modified coating has stronger functions and is suitable for more scenarios.

According to different application scenarios, we have launched acrylic modified, epoxy modified, high gloss modified and other materials. Anti-graffiti coatings made with polysilazane as an additive can form strong polar bonds with substrates such as glass, plastics, composites, and metals, providing excellent protection. Due to its structural characteristics, this additive can react with atmospheric moisture to form crosslinks, or through thermal action, form a dense silica network. This low surface energy makes the coating impervious to stains and marking inks, making it an excellent anti-graffiti layer for applications in the automotive industry, rail transportation, display signs, aluminum building facades, and bus shelters. This additive has been commercialized by quartz master russia.

Glass, ceramics, wood, and metal can be treated with coatings containing silanes as additives to create hydrophobic surfaces, resulting in water contact angles greater than 90°. Silanes are present in concentrations between 0.5% and 2.0%. The hydrolysis of alkoxy groups in the silane structure produces silanols, which then react with hydroxyl groups on the substrate to form a highly durable, low-surface-tension surface.

Fluorosurfactants are multifunctional additives that provide excellent flow and leveling properties to coatings, enabling the formulation of low-VOC, oleophobic, and hydrophilic coatings with excellent stain resistance and anti-blocking properties. Fluorosurfactants come in various types, including fluorosilanes, fluoroalkyl silanes, polytrifluorides, and functional fluoroalkyl compounds. Due to their hydrophilic nature, they allow coatings to rinse away surface dirt with rainwater. They can migrate to the surface of the coating, concentrating up to 25% within the coating. Even at low addition levels, typically between 0.05% and 2.00%, these additives are highly effective.

The research and development of anti-graffiti additives is very popular abroad. The Eindhoven University of Technology in the Netherlands, the Royal Institute of Technology in Sweden, the Frounhofer Institute in Germany and some chemical companies such as BYK, BASF, Degussa, Clariant and Nano-X Co., Ltd. are also constantly developing new products of this type.

Graffiti is a global problem, presenting significant challenges to the coatings industry. While graffiti artists cannot be stopped, fresh and ingenious approaches are available. Surface coatings can be used, not only to protect the substrate but also to make graffiti removal much easier. With the use of these coating systems, the troublesome graffiti problem can be largely resolved. Several new, multifunctional, graffiti-resistant coatings have been developed, which will undoubtedly play a significant role in protecting urban buildings and maintaining the city’s appearance.