Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Polysilazanes are ceramic prepolymers with a silicon-nitrogen backbone.

In recent years, they have developed into high-performance resins used in protective coatings for vehicles, commercial and residential buildings, and industrial plants.

Compared to polysiloxanes and fluoropolymers, polysilazanes offer superior surface hardness and scratch resistance, comparable aging and corrosion resistance, and additional ease of cleaning.

Merck is a global commercial manufacturer offering a comprehensive portfolio of organic and inorganic polysilazanes.

Beginning with organic polysilazanes, we will focus on Merck’s Durazane 1500 resin and share its properties and applications.

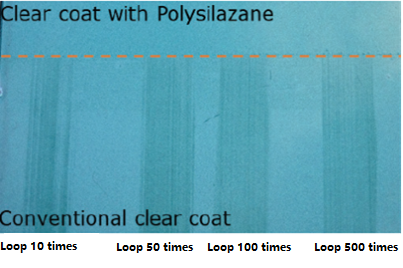

Surface hardness and scratch resistance:

Polysilazane coatings exhibit excellent surface hardness, scratch resistance, and abrasion resistance. For example, a coating based on organopolysilazane has a pencil hardness of 5H after seven days of curing at room temperature, while a coating made from a commercial methyl silicone resin has a hardness of B under the same curing conditions.

The image shows a scratch test conducted on a metal substrate coated with a color paint layer and a polyurethane clearcoat. The upper portion of the substrate was further coated with a polysilazane hardcoat. The polysilazane-coated area exhibited excellent scratch resistance after 500 scratch cycles, while the uncoated area showed noticeable scratch marks even after 10 cycles.

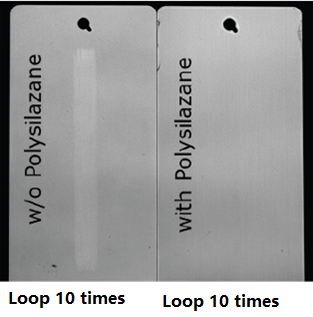

Polysilazane can also be used as a scratch-resistant resin for pigmented coatings. As shown in the figure, in the same scratch test, a titanium dioxide-based white coating containing a polysilazane resin (shown above, right) exhibits excellent scratch resistance, while the control, a coating without polysilazane, is severely scratched.

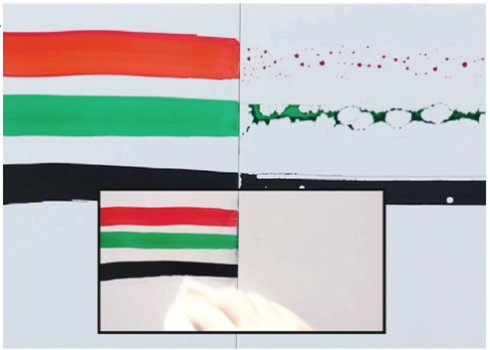

Easy to clean performance:

Organopolysilazane-based coatings are hydrophobic, with typical water contact angles in the range of 95-105°. Furthermore, their low surface energy provides excellent non-stick, anti-graffiti, and easy-to-clean properties.

The figure demonstrates the anti-graffiti properties of polysilazane coatings. Three different colors of permanent markers were used to draw a line from an uncoated surface to an organopolysilazane-coated surface. The coated surface exhibited significant ink repellency, which could be easily removed with a dry, detergent-free cloth. However, the uncoated surface showed significant marks that were difficult to clean with a cloth.

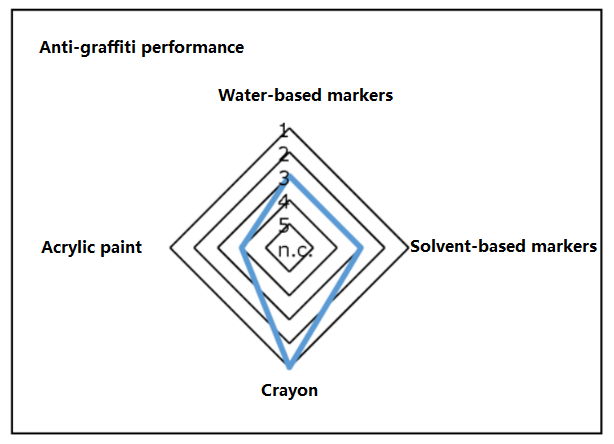

According to standard test methods, what level of anti-graffiti performance can a coating based on polysilazane Durazane 1500 achieve?

Test Method: ASTM D6578

Graffiti Materials: Green Eddy 8400 CD/DVD/BD Marker; Black Eddy 3000 Permanent Marker; Blue Crayon; Red Rico Design Acrylic Spray Paint.

Graffiti Resistance Rating: Level 1-5.

Cleaning Materials for Each Level:

Level 1 – Dry cloth

Level 2 – Neutral detergent solution (Hartmann Baktolin® sensitive wash)

Level 3 – Limonene-based cleaner (3M Industrial Cleaner – IC Cleaner Spray)

Level 4 – Isopropyl alcohol

Level 5 – Methyl ethyl ketone

n.c. – Do not clean

As can be seen from the anti-graffiti level marked by the blue line in the above figure, the coating based on the organic polysilazane Durazane 1500 has good anti-graffiti performance.

Merck polysilazanes’ anti-graffiti and easy-to-clean properties have already been used in German railways and commercial buildings.

In summary, polysilazane offers optimal protection for a wide variety of surfaces. Its unique Si-N backbone and side chain chemistry contributes to its dynamic structure-property relationship and numerous advantages, including strong and durable abrasion resistance and excellent easy-cleaning properties. It is a versatile resin, and polysilazane-based coating systems can also be used for antifouling, anti-snow/anti-icing, and many other applications.

If you feel that Merck polysilazane is too expensive, or the product performance does not meet your needs, our company can provide an equivalent product to Durazane 1500, or we can customize the synthesis according to your needs.