Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Introduction:

The diversity of the universe allows us to always maintain our infinite imagination of life in the universe. In order to better understand the meaning of life and the mysteries of the universe. Let us explore from the elemental composition of the earth…

From the evolution of the earth, our life is an organic matter composed of eight main elements, including hydrogen, carbon, nitrogen, oxygen, sodium, phosphorus, sulfur, and potassium. The word “organic” originally means “living, biological”.

Cosmic science research shows that the organisms on Earth are composed of carbon as the basic unit, also known as carbon-based life. So in this vast universe, are there other elements that form life as the basic unit? For example, silicon-based life forms. Let us explore the mystery of “silicon” in the evolution of world civilization through continuous scientific exploration and innovation.

Silicon, chemical symbol Si, formerly known as silicon. Silicon, which accounts for about 27% of the elements in the earth’s crust, exists in large quantities in sand, rocks, and minerals in the form of silicon dioxide and silicates. It is used in semiconductors, refractory materials, glass, ceramics, construction and other fields. The purification technology of industrial silicon smelted from ordinary sand and gravel has undoubtedly become the biggest challenge for mankind. We usually call silicon with a purity of 95-99% industrial silicon. Single crystal silicon made of high-purity polysilicon with a purity of 9-11 nines is the key basic material for semiconductor silicon wafers ranging from 2 to 18 inches, and has become an essential material for manufacturing modern industrial “petroleum” chips. It is gratifying that the production level of my country’s domestic semiconductor 12-inch large silicon wafers and polished wafers has reached the international leading level, and carbon-based chips are also expected to surpass it, breaking the 90% global chip monopoly of the five major suppliers in Japan, Germany and South Korea.

Unlike the complete structure of single crystal silicon, organosilicon refers to an organic compound containing Si-C bonds. It usually forms a covalent structure, such as silicon-carbon bond, silicon-oxygen bond, and forms polysiloxane, polycarbosilane, and polysilazane as a skeleton. At the same time, it can also be linked with organic molecules such as fluorine and sulfur to form different compounds. Therefore, the physical and chemical properties of organosilicon compounds not only have the electrical, thermal conductivity, and mechanical properties of silicon, but also have unique heat resistance, chemical corrosion resistance, flexibility, insulation, etc. It has become a research hotspot in the fields of lubricants, electronic materials, industrial coatings, sealing materials, and medical materials. It is known as the “industrial MSG” and is often used as a general additive. It is widely used in electronics, electrical appliances, construction, building materials, aviation, aerospace, chemical industry, medicine, photovoltaics and other fields. There are many types of organosilicon compounds, including polysiloxane, polynitrosilane, polycarbosilane, etc. Among them, polysiloxane is the largest, most studied, and most widely used type of organosilicon compounds, accounting for more than 90% of the total amount. Polycarbosilane, as a polymer compound that is a precursor of silicon carbide in high-tech new materials, is mainly used in the military and high-tech fields to prepare silicon carbide fibers and silicon carbide ceramic-based composites, as well as ceramic materials such as antioxidant and laser ablation-resistant coatings.

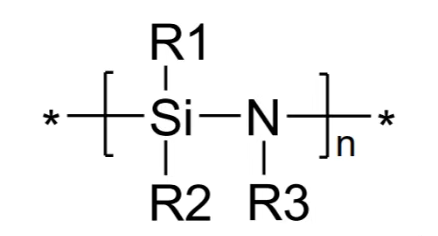

Polysilazane, an organic-inorganic hybrid polymer with a Si-N bond structure as a repeating main chain, is a silazane polymer. Due to the unique Si-N-C structure of polysilazane, the silicon-nitrogen chain and carbon-nitrogen chain formed by covalent bonds give polysilazane high hardness, ultra-thin varnish, good hydrophobicity (maintaining a 95° water contact angle for a long time), excellent adhesion to most substrates, and special physical and chemical properties such as resistance to high and low temperatures, heat insulation, insulation, corrosion resistance, wear resistance, weather resistance, radiation resistance, waterproof, mildew resistance, salt spray resistance, graffiti resistance, self-cleaning, easy demoulding, etc. However, due to its relatively active and difficult-to-tame elemental characteristics and complex preparation technology, it has been neglected by us for nearly a century.

However, compared to the overcrowded and overcapacity polysiloxane, in this world of organosilicon compounds as numerous as stars, the unique “silazane” galaxy in the universe has attracted less attention. As a result, high-performance materials such as silicon nitride and silicon carbide with silazane as precursor molecules, and key materials such as polyurethane modified coatings for original automotive paints, nano-crystal coating protection for automotive paints, high-end lubricating coatings, mechanical anti-corrosion coatings, fire-resistant coatings, exhaust pipe anti-corrosion coatings, and even linear phenolic resins, important photoresist compounds, polyurethane modified composite materials, and modified materials of epoxy resins, key auxiliary materials for carbon fiber composites, have long been monopolized and embargoed by a few foreign companies, and the prices are extremely expensive.

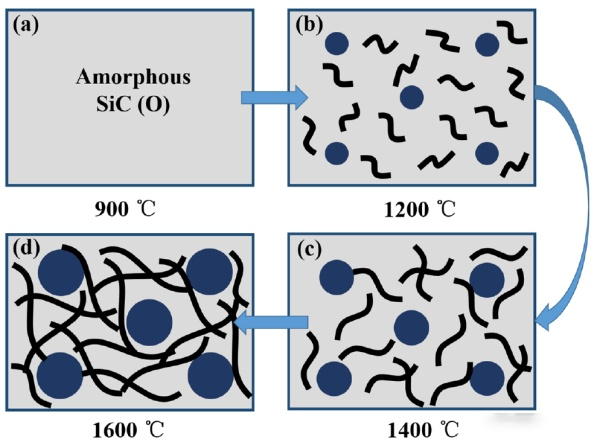

The current status of domestic polysilazane application research shows that most applications are concentrated in the field of ceramic precursors based on the properties of polysilazane (1000-1500℃). However, the application research of polysilazane resin as high-end functional industrial coatings, modified composite materials, and adhesive industry is obviously less. The main research focuses on the technical barriers of the national strategy of the Chinese Academy of Sciences, including aerospace of the Institute of Silicic Acid, synthesis research and development of the Institute of Chemistry, marine corrosion protection of Ningbo Institute of Materials, and application development of new materials such as aerogels, silicones, and battery negative electrodes of Wuhan Institute of Advanced New Energy. And a few companies are limited to the experiment and small-scale production supply of high temperature corrosion resistance, solid polysilazane resins and oligomers.

Quartz Master New Materials has been focusing on the research and development and industrialization of organic polysilazane-derived ceramic coatings, as well as the application research of organic silazane synthesis-polymerization-curing-cracking under the medium and high temperature properties of polysilazane (300℃-1000℃) for many years. Through grafting, chain extension, modification and other reactions and conditions, it prepares target polymers and advanced modified composite materials with molecular weights of 2×103 to 1.6×105, improves the product performance of domestic silazane polymer resins and their applications in related fields, and accelerates the localization substitution rate of new polysilazane resin materials.

In view of the fact that the technology for preparing high-purity silane is mainly in the hands of a few companies in the United States, Japan, and Germany, the domestic synthesis method of silazane is still immature, the molecular weight of polymers is generally low, and the heat resistance is relatively poor. Quartz Master New Materials Co., Ltd., stay true to its original aspiration and forge ahead. Willing to be the “catalyst” for the development of the polysilazane industry, providing leading products and technical guides for customers’ innovative needs; with the spirit of picking the crown jewel in the field of silazane chemicals, creating unlimited possibilities for the application of silicone technology. Using the internationally common UCC production process, continue to explore mature high-molecular-weight silazane synthesis methods, prepare polysilazane resins with specific structures and international market competitiveness and their derivative ceramic products PDC, and practice the company’s mission to completely break the international “stuck neck” technology of silicone and revitalize the national new materials industry.