Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

With the advancement of technology and the continuous development of modern industry, the demand for equipment operating in high-temperature environments is increasing, such as high-temperature pipelines, chimneys, exhaust pipes, and aircraft engine casings. Without proper protection, these equipment are easily oxidized or corroded at high temperatures, making high-temperature resistance an indispensable component of modern industry. High-temperature-resistant coatings generally refer to specialized coatings that can withstand high temperatures for a specified period of time while maintaining some mechanical properties. Based on the film-forming material, they are generally categorized as organic, inorganic, and hybrid organic-organic high-temperature-resistant coatings. Silicone-based high-temperature-resistant coatings are the most widely used of these organic high-temperature-resistant coatings.

Silicone resins (also known as polysiloxanes) are a general term for polymers with a backbone composed of alternating silicon and oxygen atoms, with various organic groups attached to the silicon atoms. Because the bond energy of the Si-O bond (460.5 kJ/mol) in silicone resins is significantly higher than that of C-O bonds (358.0 kJ/mol) and C-C bonds (304.0 kJ/mol), silicone resins exhibit excellent high-temperature and weathering resistance and are increasingly becoming the primary film-forming agent in organic high-temperature-resistant coatings. This study focuses on the current status and development trends of high-temperature-resistant coatings using silicone resins and their modified resins as film-forming agents.

Silicone high temperature resistant coating

Silicone high-temperature resistant coatings refer to coatings that use silicone resin as a film-forming substance and are formulated by adding heat-resistant pigments, fillers, additives, solvents, etc. The type of silicone resin, the type of pigments and fillers, and the ratio of resin to pigments and fillers have a great influence on the high-temperature resistance.

In terms of selecting and combining heat-resistant fillers, in addition to conventional titanium dioxide, aluminum powder, mica powder, and glass powder, hollow insulating fillers can further enhance the thermal insulation performance of high-temperature resistant coatings. For example, Wu Lianfeng et al. enhanced the high-temperature resistance of the coating by combining heat-resistant fillers such as mica powder and nano-silica with silicone resin, while also reducing the thermal conductivity of the coating by adding hollow microspheres. Comparing the sizes of different insulating fillers, they found that smaller fillers reduced the accumulated porosity and increased the pigment-to-binder ratio, helping to compensate for porosity and thermal shrinkage, further improving the coating’s high-temperature resistance. This allowed the coating to maintain a high hardness even after enduring 500°C for one hour.

Common organosilicon high-temperature resistant coatings cannot be fully cured at room temperature and require high-temperature baking or subsequent high-temperature use to be completely cured. In actual applications, the paint film may fail prematurely.ZhengZhou Quartz Master New Materials has developed a one-component, room-temperature-curing silicone high-temperature resistant coating (EK-S02). This one-component, room-temperature-curing silicone high-temperature resistant coating not only achieves high-temperature resistance of 600°C, but also has excellent corrosion resistance.

Currently, silicone heat-resistant coatings are mainly solvent-based, with water-based coatings being less common. Compared to solvent-based silicone heat-resistant coatings, water-based silicone heat-resistant coatings have obvious environmental advantages.

Although silicone high-temperature resistant coatings can achieve good high-temperature resistance by adjusting the composition of high-temperature resistant pigments and fillers, due to the characteristics of silicone resins themselves, most of them have poor adhesion and mechanical properties on different substrates. Many organic resins usually have good mechanical properties such as adhesion, bending resistance and impact resistance. Therefore, silicone resins can be modified through organic resins to improve the overall performance of silicone coatings while maintaining good high-temperature resistance.

Modified silicone high temperature resistant coating

Currently, there are two main approaches to improving silicone heat-resistant coatings:

The first is to modify the silicone resin to improve the overall performance of the coating while maintaining good heat resistance.

The second is to research new high-temperature resistance mechanisms and use new high-temperature-resistant pigments and fillers for modification.

1).Acrylic modified silicone high temperature resistant coating

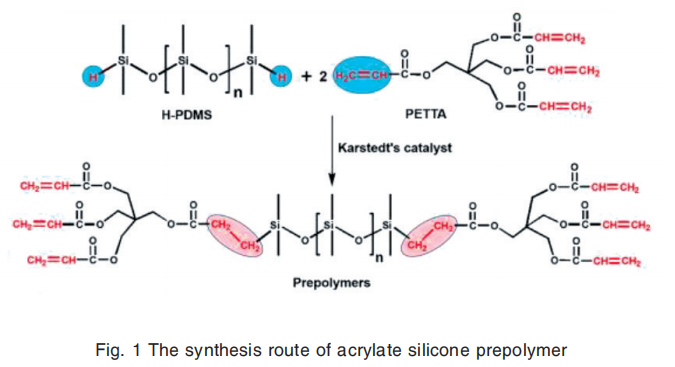

Acrylic resins generally have good mechanical properties. Modifying silicone resins with acrylic resins can not only improve the heat resistance of acrylic resins, but also significantly enhance mechanical properties such as hardness and adhesion of silicone resins. In addition, by introducing UV curing technology into acrylic resins, rapid curing can be achieved at low temperatures without generating volatile organic compound emissions.

Multifunctional acrylic silicone prepolymers were obtained through a one-step hydrosilylation reaction of pentaerythritol tetraacrylate and hydride-terminated polydimethylsiloxane. These prepolymers contain three acrylate groups at each end of the polysiloxane chain, allowing them to participate in UV curing. Consequently, they exhibit high UV curing activity and rapidly cure with the addition of a small amount of photoinitiator. Films prepared solely from the resin can withstand temperatures approaching 400°C, demonstrating promising application potential in high-temperature resistance applications.

2).Polyester modified silicone high temperature resistant coating

Polyester resins have many attractive properties, such as excellent impact resistance, adhesion, and chemical resistance. Combining polyester resins with silicone resins can improve the silicone resin’s mechanical properties, such as adhesion and flexural strength, while also improving the polyester resin’s heat and water resistance.

ZhengZhou Quartz Master New Materials uses polyester and fluorosilicone resin as raw materials to prepare a series of polyester-modified silicone resins with varying silicon contents. These resins exhibit not only excellent heat resistance but also good resistance to yellowing and water. The authors tested fluorosilicone resin contents ranging from 10% to 50%. The authors found that a 50% fluorosilicone resin content exhibited optimal heat resistance. Furthermore, as the fluorosilicone resin content increased, the yellowing and water resistance of the composite films also gradually improved.

Using polyester-modified silicone resin as the primary film-forming material and combining it with various high-temperature-resistant pigments and fillers, a series of high-temperature silicone coatings capable of long-term use at temperatures between 450°C and 500°C have been successfully prepared. These coatings not only exhibit excellent mechanical properties such as hardness and adhesion, but also exhibit very good hot hardness at 200°C, reaching a maximum of H.

3). Polyurethane modified silicone high temperature resistant coating

Polyurethane resin has good adhesion, toughness, wear resistance and solvent resistance. Grafting polyurethane into silicone resin can improve the adhesion, toughness, wear resistance and solvent resistance of silicone high-temperature resistant coatings, thereby obtaining silicone high-temperature resistant coatings with better overall performance.

A series of high-temperature-resistant, hydrophobic, cross-linked polysiloxane-based polyurethane films were prepared using a sol-gel process. 3-Aminopropyltriethoxysilane was introduced into the polysiloxane-based polyurethane system, followed by dehydration and condensation to form a three-dimensional network structure. The resulting resin exhibits excellent heat resistance, with an initial maximum decomposition temperature of 475°C, as well as good water resistance and tensile strength.

By reacting isocyanate with a hydroxyl-containing silicone resin, a polyurethane-modified silicone resin was successfully modified to produce a polyurethane-modified silicone heat-resistant coating with excellent adhesion, flexibility, and impact resistance. The coating also cures at room temperature and withstands temperatures of 700°C for one hour without delamination, shedding, or blistering. This polyurethane-modified silicone heat-resistant coating not only achieves exceptional heat resistance but also imparts exceptional overall performance.

4).Polyimide modified silicone high temperature resistant coating

Polyimide refers to a class of polymers containing an imide ring (-CO-NR-CO-) in the main chain. It has excellent high-temperature resistance and mechanical properties, good insulation and chemical corrosion resistance. It is one of the organic polymer materials with the best overall performance and is a high-performance polymer material widely used in extreme environments.

A high-temperature resistant and anti-corrosion coating is formulated using polyimide-modified silicone resin as the main film-forming substance, supplemented with polyethylphenyl silicone resin and bisphenol A unsaturated polyester resin. High-temperature resistant fillers such as aluminum powder and talc are added to create this coating. It can withstand temperatures of 450-500°C for over 30 hours, exhibits excellent adhesion, and is free of blistering and cracking. It also exhibits excellent anti-corrosion properties, with a salt spray resistance of >1,000 hours.

5). Epoxy modified silicone high temperature resistant coating

Epoxy resins typically possess excellent mechanical properties and strong bonding strength. By introducing epoxy groups into silicone resins, the coating’s bonding strength can be effectively improved while maintaining good high-temperature resistance, giving silicone heat-resistant coatings superior overall performance. Wang Ce et al. successfully prepared a high-performance epoxy-modified silicone heat-resistant coating by combining an epoxy-modified silicone resin with an amino resin and optimizing the filler, dispersant, and solvent combination. The resulting film exhibited excellent adhesion both before and after heat treatment. After 5 hours of exposure to a 600°C high-temperature test chamber, the film showed no cracks or wrinkles, and no discrepancies from its pre-test state. A cross-hatch scratch was performed on the sample surface with a scriber knife, and the number of droplets at the intersection of the cuts was ≤5%.

Experiments have shown that by combining silicone resin with self-made silanized epoxy resins of varying structures and functionalities, a high-temperature silicone coating with excellent adhesion, outstanding heat resistance, and corrosion resistance can be obtained. Compared to pure silicone resin, the coating containing 25% silanized epoxy resin exhibits improved thermal performance, as evidenced by a delayed degradation temperature and significantly increased carbonization rate.

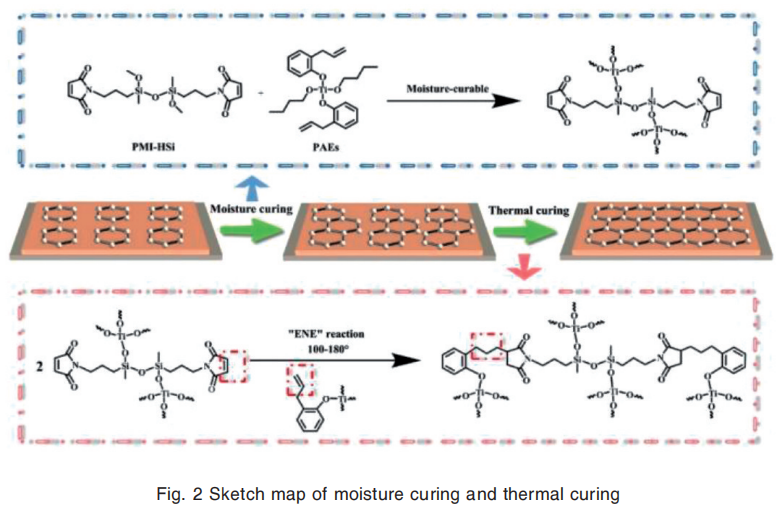

6). Organic-inorganic composite high temperature resistant coating

The coating formed by hybridizing inorganic materials and silicone resins through sol-gel and other methods is called organic-inorganic composite high-temperature resistant coating. This composite coating can not only improve the high-temperature resistance of the coating, but also improve the mechanical properties of the coating such as hardness, adhesion, and flexibility.

A polyester-modified silicone resin with carboxyl-terminated water-soluble groups undergoes in-situ neutralization and salt formation in a modified titanium sol aqueous system, resulting in a titanium-containing waterborne polyester-modified silicone resin with uniformly distributed nano-titanium dioxide particles. Because the nano-titanium dioxide particles protect the ester bonds from hydrolysis and oxidation, the coating does not become viscous or soften under heating, maintaining good hardness even at high temperatures. The coating’s thermal hardness at 150°C can be increased from B to 2H.

During the silicone resin synthesis process, an alkoxy coupling agent monomer containing epoxy groups is added to the alkoxysilane monomer for hydrolysis and condensation, forming a high-temperature-resistant composite silicone resin composed primarily of Si-O-Si bonds and supplemented with flexible segments. During the sol-gel process, an inorganic nanosol is added for doping, forming a honeycomb protective structure and improving the resin’s high-temperature resistance. The resulting coating exhibits no noticeable discoloration, fading, cracking, or peeling after baking at 600°C for 40 minutes, and exhibits Class 1 adhesion.

By leveraging the “secondary film-forming” effect of low-melting-point glass flakes and optimizing the ratio of silicone resin, low-melting-point glass flakes, and fillers, a high-temperature-resistant coating with excellent overall performance was developed. The coating maintained a Class 1 adhesion even after being held at 700°C for 6 hours. Microscopic observation and comparative study of the surface morphology of the high-temperature-resistant coatings after different high-temperature treatments confirmed that the low-melting-point glass flakes can act as a secondary film after melting at temperatures above 400°C. This low-melting-point glass flakes achieve a transition from an organic coating to an inorganic coating at high temperatures, thereby achieving prolonged high-temperature resistance.

A new zirconium hybrid silicone resin was synthesized using zirconium n-propoxide as a structurally controlled component in the copolymerization and condensation of alkoxysilanes. The resulting product exhibits superior high-temperature resistance and adhesive properties. Heat loss analysis shows that the heat resistance of the silicone resin is significantly improved with the addition of zirconium. At 1000°C in an argon atmosphere, the residual mass increases from 31.58% to 84.71%, and the adhesiveness is nearly tripled.

Conclusion

After decades of development, silicone high-temperature-resistant coatings have yielded a series of research results both domestically and internationally, with their temperature resistance increasing from an initial 200°C to nearly 1000°C. With the advancement of science and technology, the application scenarios for silicone high-temperature-resistant coatings are expanding, and the requirements for coating performance are becoming increasingly stringent. Furthermore, with increasing environmental awareness, silicone high-temperature-resistant coatings also need to develop green and environmentally friendly approaches. Combining research findings in silicone modification and organic-inorganic silicone composites, it is of great significance to develop new technologies and processes that offer excellent workability, balanced mechanical properties, environmental friendliness, and low cost.