Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

1.Basic Introduction to Metal Powder Coatings and Acrylic Powder Systems

As two “high-value” products in the powder coating industry, metallic effect powder coatings and acrylic powder coatings have always shown popular in the market. In recent years, the domestic enterprises’ metallic effect powder coating technology has made rapid progress, and at the same time, acrylic powder coatings have been increasingly used in the domestic powder coating market.

Metallic powder coatings are solid powder coatings composed of resin, curing agent, pigment, filler, and additives. Aluminum powder, pearlescent pigments, and other effect pigments are bonded to the powder coating through bonding processes, resulting in a coating with a metallic texture and vibrant color. This product is primarily used for surface protection and decoration of steel, aluminum, aluminum alloys, and other metal substrates. Its formulation and production process are designed to meet customer demands for a metallic appearance and stable on-site application.

Acrylic powder coatings are thermosetting powder coatings composed of acrylic resins, curing agents, pigments, fillers, and additives. Thermosetting acrylic resins are copolymerized with acrylic monomers containing reactive groups to produce an acrylic resin with an acrylic backbone and reactive functional groups on the side chains. The acrylate groups may contain glycidyl (epoxy) groups, or hydroxyl and carboxyl groups.

Acrylic resins are synthesized using monomers such as acrylic acid and methacrylic acid, as well as esters. In addition to double bonds for addition polymerization, some of these monomers also contain reactive groups such as hydroxyl, carboxyl, glycidyl, and amido groups. These reactive groups impart reactive groups to acrylic resins, allowing them to crosslink and cure with curing agents to form a film.

2.Application test of acrylic resin in powder coating

2.1 Design Ideas

Metallic-effect powder coatings primarily rely on the combination of a base powder and metallic pigments to create a product with excellent results and stable application. Setting aside the binding process, the core of the formulation lies in the design of the base powder and the choice of metallic pigment. Years of experience have concluded that the base powder must meet the dispersion and distribution requirements of the metallic pigment, and together with the base color, highlight the metallic pigment effect.

In summary, a primer needs to provide a clear film, strong wettability, and excellent leveling. Acrylic powder coatings excel in these areas, exhibiting excellent wetting and distribution of metallic pigments while maintaining excellent leveling.

The test direction is to use GMA acrylic resin + DDDA powder system as the base powder, spray it with aluminum powder and pearlescent pigment of different particle sizes, and compare the differences in the coating surface.

2.2 Preparation and test results of acrylic metal powder effect powder

Testing the dispersion of aluminum powder in a transparent system: Pure silver metallic powders created by combining transparent powder with aluminum powder, particularly silver-spangled aluminum powder, are a mainstream product in the market.

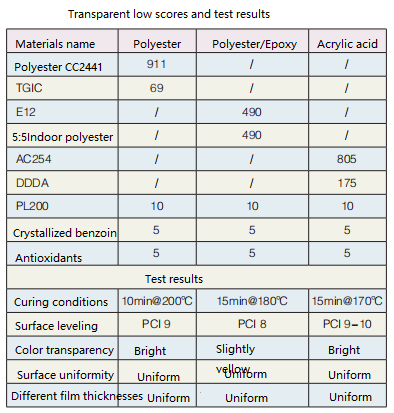

We selected three primer systems: polyester/TGIC, polyester/epoxy, and acrylic/DDDA. We also formulated an acrylic + polyester system. We added 5% PCR212 and 2% Powdal 8550, respectively, to compare the metallic effect and film appearance.

As can be seen from the formulas in the table above, compared to conventional polyester/TGIC and polyester epoxy coatings, these coatings exhibit no clouding, often associated with pigments, nor significant color variation with film thickness. However, we did find significant color variation with significant differences in film thickness or at the sagging corners of the workpiece.

By leveraging the wettability of acrylic and combining it with the metallic texture of aluminum powder, a new paint-like effect can be achieved. Considering the hiding power of metallic pigments, the pigment dosage can be reduced.

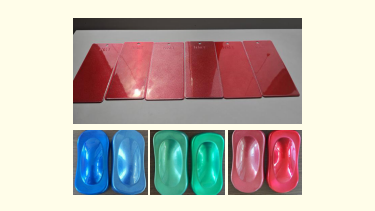

After binding the base powder with the desired metallic effect pigment, the aluminum powder is evenly incorporated into the acrylic film to sublimate the acrylic effect, forming a uniform, translucent, and translucent aluminum coating. The color can be achieved in various shades, such as red, yellow, blue, and green, depending on the type of acrylic. Combined with the metallic effect of the base coat, mirror silver can create a paint-like effect, while fine silver shimmer can achieve a similar effect. These products have broad potential for development in the wheel industry, especially in the aftermarket, where mid- and surface-integrated components are integrated.(Definition of mid-top and bottom-top integration: Based on an acrylic powder coating system, it provides a single coat of color to replace the current two-coat process of color paint + acrylic clear powder.)

3.Key points and application prospects in application

While the advantages of acrylic acid have brought new benefits to powder coatings, its drawbacks should not be overlooked, and they are key points we must address in our daily work. Acrylic acid’s drawback is its potential to contaminate other powder systems. Acrylic powder coatings are susceptible to interference during production and application, requiring stringent environmental and construction conditions. Whether it’s the aforementioned paint-to-powder conversion or overcoat application, contamination is an unavoidable issue.

Furthermore, acrylic coatings have a relatively high melt viscosity, poor pigment dispersion, and the resin itself is inherently rigid, resulting in lower impact strength than other powder coatings. Acrylic acid is also costly, significantly more expensive than other powder coatings, primarily due to the price of the resin. We urge domestic acrylic manufacturers to conduct further research and development to develop cost-effective acrylic resins that are suitable for the market.

As mentioned at the outset, the acrylic resin used in this study is a GMA/DDDA curing system. There are many other acrylic systems, and we can conduct further experiments and comparisons to find the optimal combination of performance and cost. In the future, leveraging the advantages of acrylic acid to develop new products while simultaneously improving and mitigating its shortcomings through raw materials, formulation design, and process development will be crucial.