Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Room 2301C, 23rd Floor, Building 1, jinghu Commercial center, No, 34, Liangzhuang Street, Eri District, Zhengzhou City, Henan province

Woours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

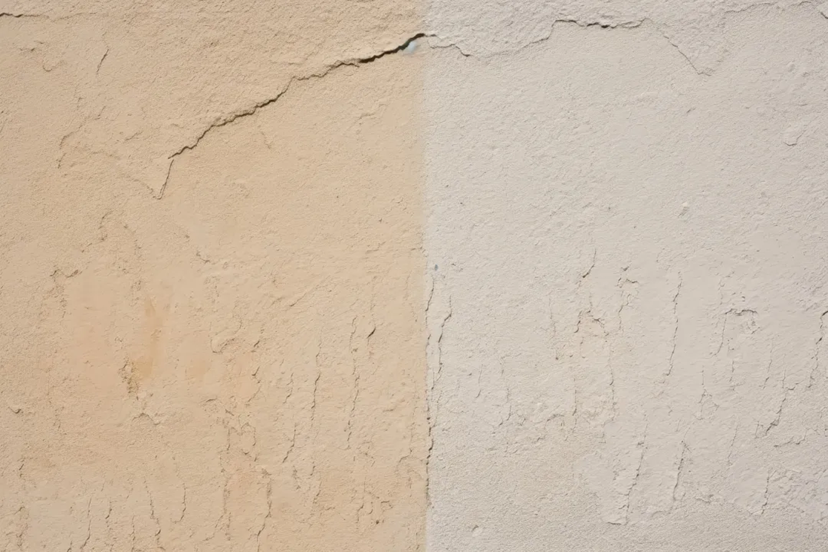

Yellowing is a type of color change in a paint film, similar to the causes of discoloration and fading. Yellowing primarily occurs when white or light-colored paints, or clear varnishes, turn yellow or even brown when exposed to sunlight, UV light, or heat.

Yellowing is related to the light resistance of the resin binder. Alkyd resins containing drying oils (high unsaturation), coumarone resins, aromatic epoxy resins, TDI-type polyurethanes, and phenolic resins tend to yellow. Furthermore, pigments with poor light resistance, such as lead white, lithopone, and anatase titanium dioxide, can also yellow. Furthermore, an excessive amount of driers can also cause yellowing in alkyd paints.

1.Causes of yellowing of paint film

1). Environmental factors

Direct sunlight (UV radiation), air, and humidity can cause paint films to age and decompose, leading to yellowing.

For example, if polyurethane coatings use aromatic curing agents, UV exposure can easily break down the urethane bonds in the coating, generating amines. Further oxidation of the aromatic amines causes molecular rearrangement, forming quinone or azo structures, which can cause yellowing and discoloration. Oily resins containing double bonds can also cause yellowing due to the oxidation of these double bonds, producing chromophores.

2). Product issues

Yellowing may also be caused by differences in the yellowing resistance of the paint itself.

For example: ① For outdoor use, the yellowing and fading rates of the paints, from fastest to slowest, are: polyurethane paint – epoxy paint – alkyd paint – amino paint – nitrocellulose lacquer – chlorinated rubber paint – acrylic polyurethane paint – fluorocarbon paint; ② For indoor use, away from direct sunlight, the yellowing and fading rates, from fastest to slowest, are: alkyd paint – amino paint – polyurethane paint – epoxy paint – nitrocellulose lacquer – chlorinated rubber paint – acrylic polyurethane paint – fluorocarbon paint.

3). Causes of additives

Common additives (such as antioxidants, anti-aging agents, UV absorbers, etc.) can also cause yellowing. Excessive use of drying agents can also cause yellowing of alkyd paint.

2.Introduction to the Yellowing Resistance Standard of Coatings

The yellowing resistance of coatings is basically implemented in accordance with ” GB/T 23983-2009 Determination of Yellowing Resistance of Wood Coatings”.

1). Yellowing Resistance Test Panel Requirements: Use white exterior-grade glazed porcelain tiles. After 168 hours of UVA-340 illumination, the ΔE* should be no greater than 0.5. Test panel size: 95 mm × 45 mm.

2). Yellowing Resistance Testing: Using a UVA-340 lamp as the light source, place the test panel in a fluorescent UV aging chamber with the following test conditions: a temperature of (60±3)°C, an irradiance of 0.68 W/m², and dryness (no condensation). Maintain continuous illumination for 168 hours. After the illumination period, remove the panel and compare it to an unexposed panel. Measure the color change using a colorimeter and record the change in units of ΔE*. The smaller the measured value, the better the yellowing resistance.

Although ultraviolet (UV) light only accounts for 5% of sunlight, its short wavelength makes it a major contributor to yellowing and reduced outdoor durability in coatings. The impact of photochemical reactions increases with decreasing wavelength, so simulating the destructive effects of sunlight on a material’s physical properties doesn’t require reproducing the entire sunlight spectrum. In some cases, simulating only short-wavelength UV light is sufficient.

The UVA-340 lamp can perfectly simulate the critical short-wavelength range of sunlight spectrum, that is, the spectrum with a wavelength range of 295~360 nm, and produce a spectrum of UV wavelengths that can be found in sunlight.

3.What to do if the paint film turns yellow

Select products according to the use environment: In order to avoid yellowing of the paint film, you must first understand the use environment of the product. If used outdoors, you can choose acrylic polyurethane paint, fluorocarbon paint and other varieties with good outdoor yellowing resistance.

Formula adjustment: Select a suitable drying agent and comprehensively evaluate its effect on yellowing, and add ultraviolet absorber if necessary.